Notable Work

Autonomous AMR charging

(Ubiquity Robotics, 2023)

Implemented autonomous charging for Ubiquity Robotics Magni AMR, by using LiDAR and camera for charging station localization based on physical and fiducial markers.

Robot DRM

(Ubiquity Robotics, 2022)

Solution that disables the robot if the Client doesn't settle debts on time or attempts to modify proprietary software. I also set up a backend which allows controlling the DRM protection remotely.

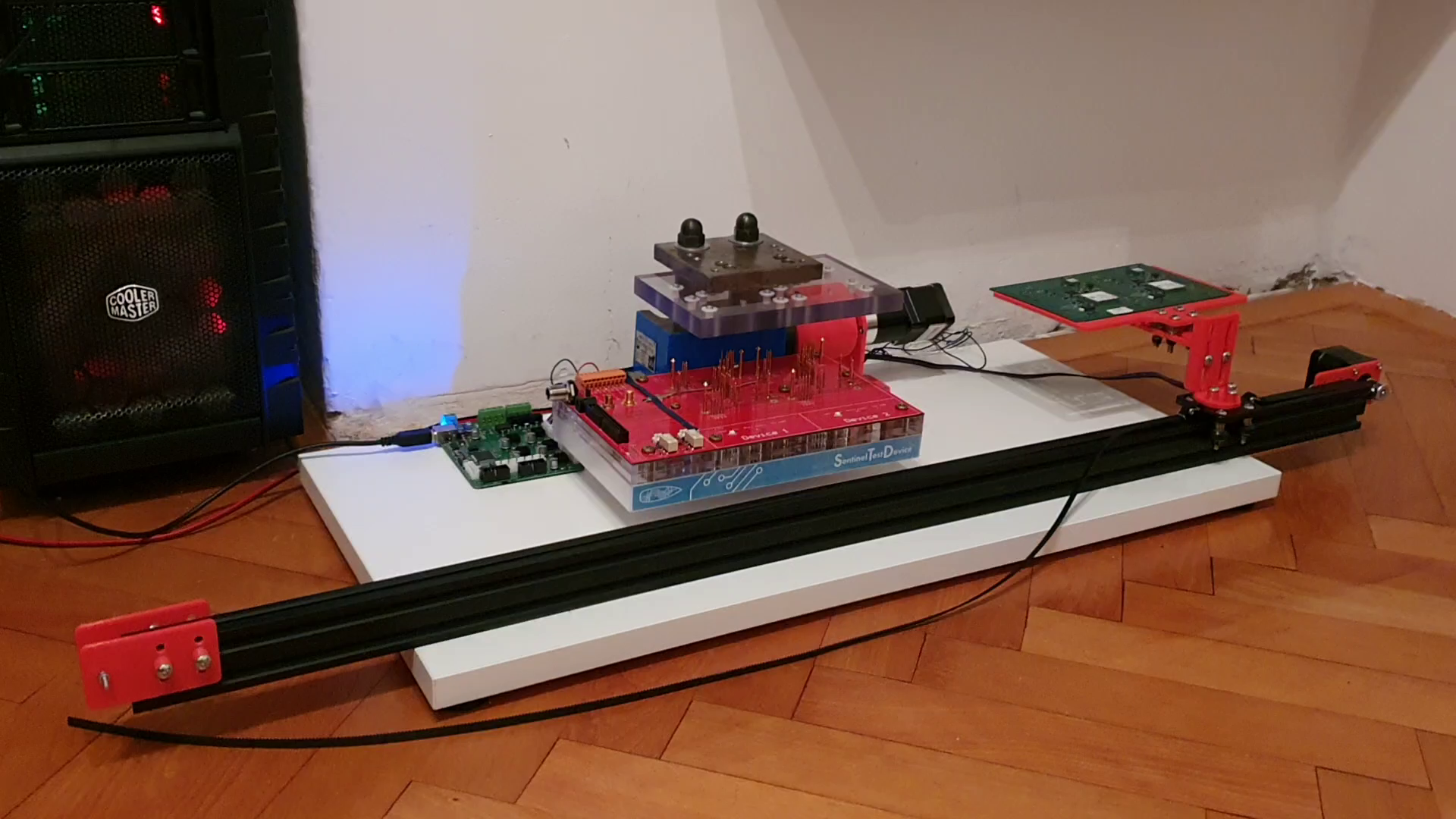

Automating PCB testing

(Sentinel Marine, 2020)

Converted a manual, hand-operated clamping mechanism for testing PCB panels into an automated solution. Additionally, I developed a custom multithreaded desktop app for controlling the testing procedure.

Bluetooth-WiFi Bridge app module

(Sentinel Marine, 2018)

The boat tracking devices developed by Sentinel Marine needed a direct connection option for the purpose of setting up software after manufacturing. For this reason, I developed a module for their mobile app which allowed connecting the tracker through a Bluetooth low energy (BLE) connection through a mobile phone to the internet.

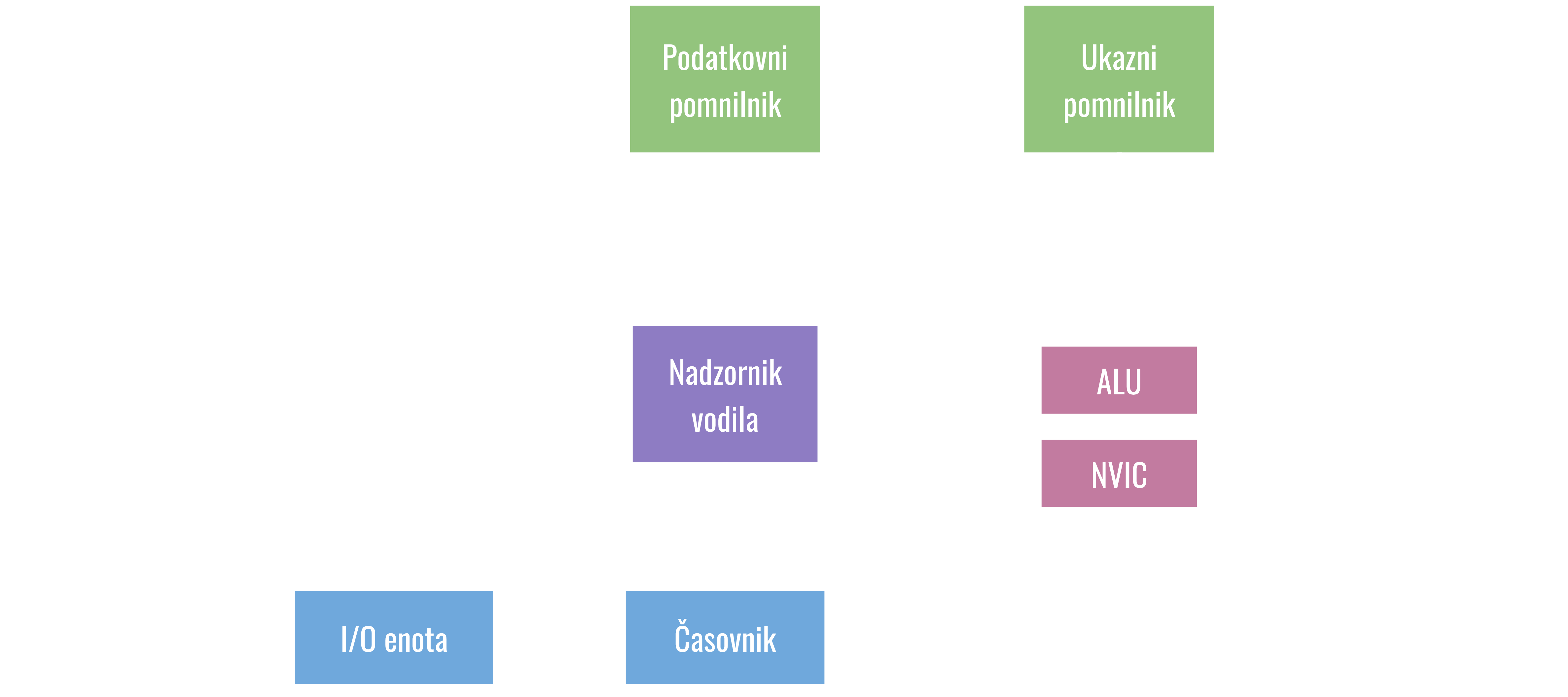

Universal Neurological Evaluator

(In progress)

As part of my master thesis, I'm developing a wearable fine motor function evaluator device, completely from scratch. For sensing fine motor functions, I'm using two 9-DOF IMUs. Measurements are captured and analyzed through a custom developed desktop application, written in Python.

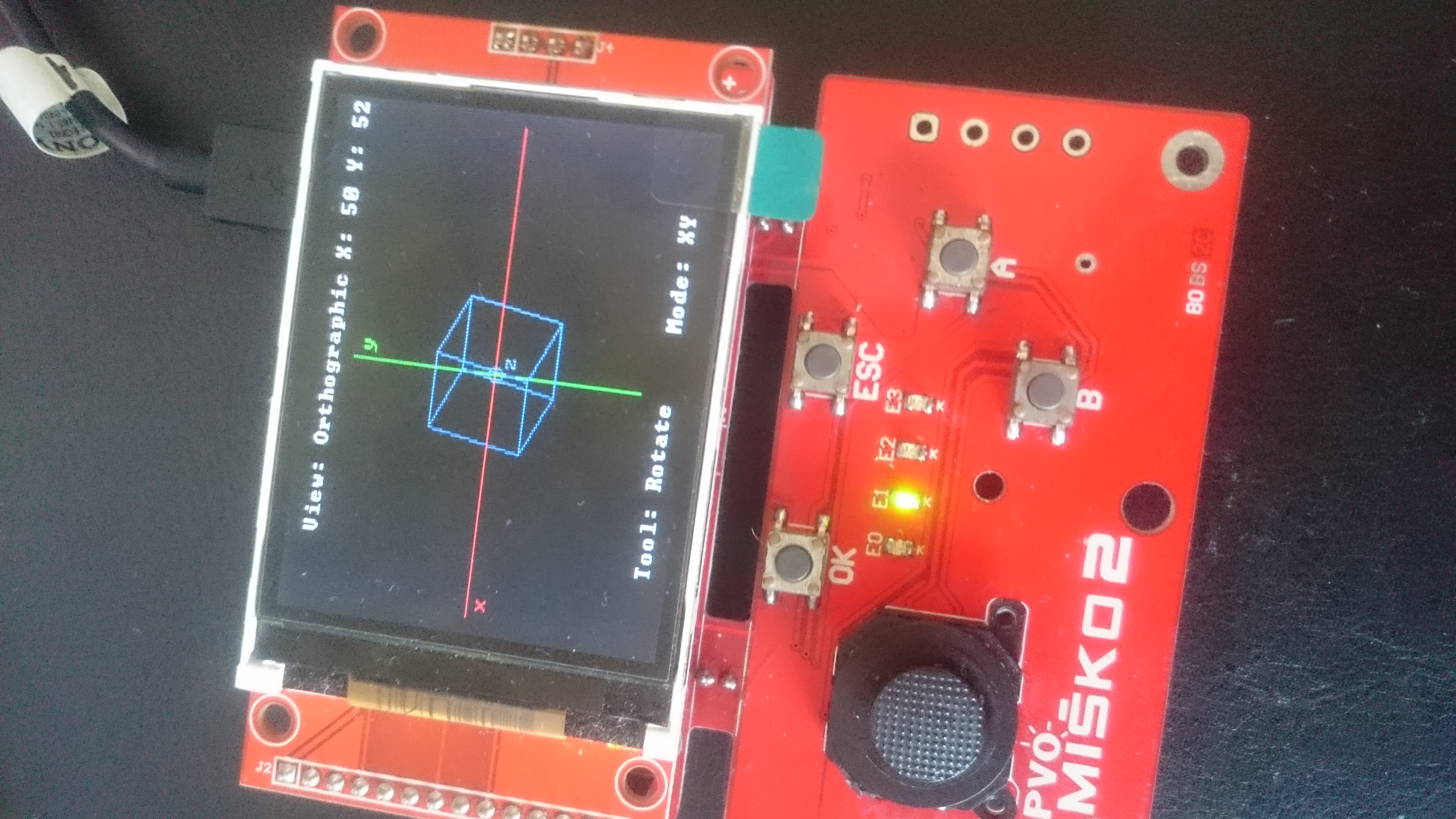

Blender, AVR edition

(2017)

Fully fledged 3D object manipulation engine, running on an ATmega328PB with only 2 kB of RAM. It was possible to translate vertices, rotate and scale. Additionally, the user could sculpt the object's shape using a brush. The object state was able to be saved and loaded from EEPROM.

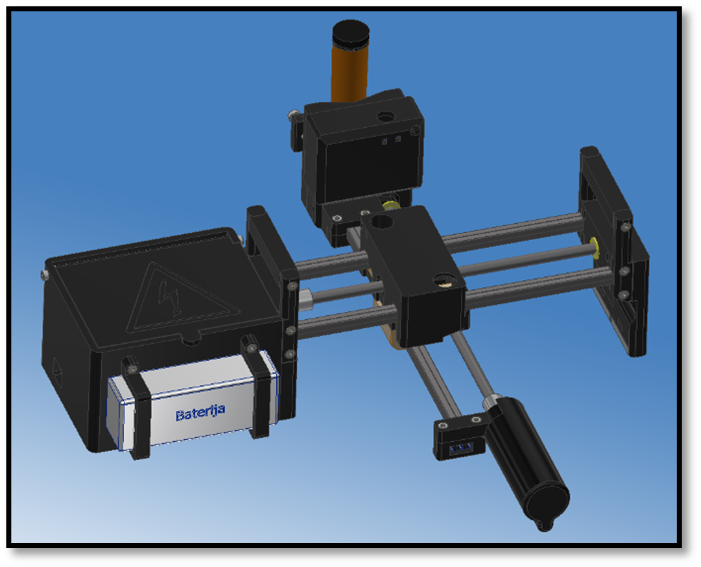

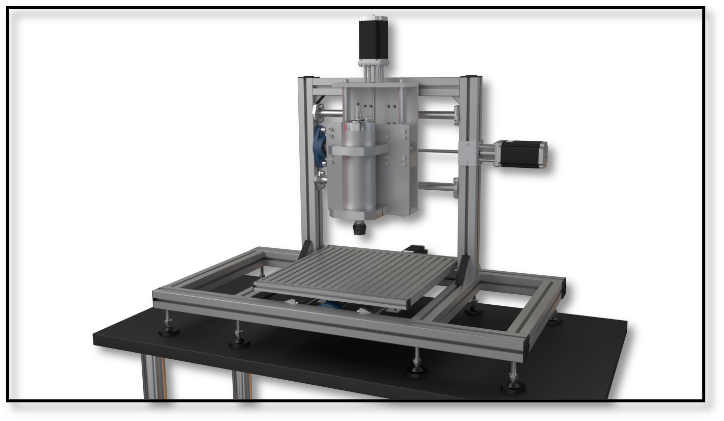

CNC milling machine from scratch

(2015)

As a final high school project, I developed a CNC milling machine with a 30x30 cm work area, completely from scratch. Development included controller firmware, a desktop app with simulation and a G-code text editor; mechanical design and a hand-etched motor driver PCB.